Flaring slot ports

Even slot ports should be flared

The normal method of flaring a slot port is to use a rollover bit in the router to run all the way around the port opening

If you are moving a lot of air, you may find that this is not sufficient

One solution is to take a length of PVC pipe and split it lengthwise into quarters

These segments can then be let into the enclosure to form a rectangular flare

The corners would be mitred at 45 degrees

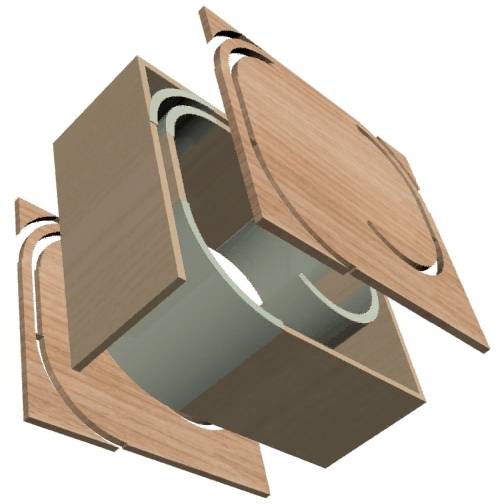

Even less work is involved if you use half segments, as shown in this photo. Not quite as neat, but effective just the same

Mark Lampi's implimentation of this idea

When calculating usable velocity, you need to make allowance for the corners being less streamlined than the rest of the flare

Modelling the flare radius as 25% smaller should do the trick. Note that the flare uses the outside diameter of the pipe as the flare

This table shows what would be achievable starting with common sizes

| Source material | Outside diameter (mm) | Model flare radius as....(mm) |

| 2 inch sewer pipe | 56 | 21 |

| 90 mm downpipe | 90 | 34 |

| 4 inch sewer pipe | 110 | 41 |

| 6 inch sewer pipe | 160 | 60 |

Smoothly flared corners could be made using a heated sheet of PVC pressed between male and female molds

The edges would need to be cleaned up with a router

This would give the same shape flare that would be achieved with a router and an impossibly huge rollover bit

It would improve the performance of the corners, although they would never be as good as a circular port

I'm only guessing, but I would say that modelling the flare radius as 20% smaller should be reasonable

This would adjust our table as follows

| Source material | Outside diameter (mm) | Model flare radius as....(mm) |

| 2 inch sewer pipe | 56 | 22 |

| 90 mm downpipe | 90 | 36 |

| 4 inch sewer pipe | 110 | 45 |

| 6 inch sewer pipe | 160 | 64 |

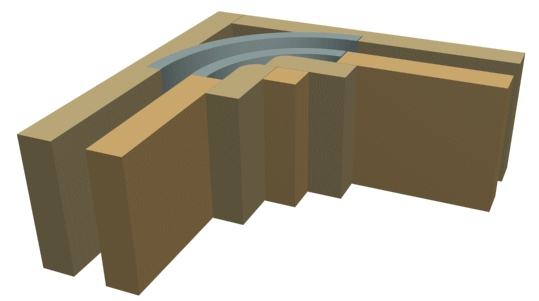

Segments of pipe can also be used to smooth any turns inside a slot port

In this example, you would need two pipe sizes

After being split and heated, PVC is quite amenable to being wrapped over a suitable former to whatever radius you need. Check out the

concentric port build gallery for ideas on how to do this

If you are increasing the radius of a segment, remember to initialy cut it larger than 90 degress

You could go even further with this idea

- An SPL champion at talkaudio in the UK, recommends that the ratio of width to height for a slot port should not exceed 5:1. He also suggests that flares for slot ports can be done quite easily with an angle grinder and some sandpaper.

-

There is a discussion comparing round ports vs slot ports

at AVSForum where Mark Seaton suggests a 3:1 ratio

- If using a slot port as part of the enclosure wall, the port appears longer. There's some discuission of slot port arrangements at diyAudio