Port Flares

Port flares make a large difference in how much air a port can pass before turbulence becomes audible

Being able to increase airflow means you can use a smaller diameter port. Since the port length is proportional to the square of the port diameter, this can make a large difference to the length of your ports. A shorter port is more likely to fit into your enclosure without any bends, further saving on noise and build difficulty. It also has less chance of "pipe mode" resonance intruding on the operating range of your subwoofer. The reduction in volume occupied by the port also means a smaller box.

Some options for making your own flares

Routed flares - up to 13mm or 36mm in radius

Make your own by routing a rollover on the supporting panel.

As above, the flare radius is limited by the router bits available - a small router will get you 13mm, full-sized routers can do up to 36mm (1-1/2")

Donuts and Smoothing Rings - up to 13mm or 36mm in radius

Donuts and smoothing rings can provide flares where space is limited. These are also popular with sonosub builders.

The flare radius is limited by the router bits available - a small router will get you 13mm, full-sized routers can do up to 36mm (1-1/2")

Heat moulded PVC Flares - up to 25, 30 or 40mm

PVC pipe can be heated with a hot air gun and pushed onto a mould with good results.

This method will produce flares up to 25mm for port diameters up to 100mm, flares up to 30mm for 150mm pipe, and flares up to 40mm for 225mm pipe.

Flared ends and joiners can be produced, but the nicest feature of this method is that you can make a one-piece port. (you can't buy those anywhere....)

Whilst making the moulds requires some work, this can be offset if you make ports for a few friends.

For countries where commercial 30mm radius flares are not available, or are too expensive to import, this method can give a

professional finish if you take your time.

Custom built - larger flares

Flares larger than those described above need to be individually built. I've built ports using an "inside out" version of

the "heat moulded" technique.

Flares for slot ports

Slot ports sometimes require a flare which is larger than you can achieve with a router.

Splitting some PVC pipe lengthwise can do the trick

Effective Length

A flared port shares part of the air in the flare with the surrounding air, meaning that the port appears shorter. The generally accepted adjustment is to subtract half the flare radius from the physical length to obtain the effective length. If both ends of the port are flared, the adjustment is done for each flare.

How large a flare is needed?

I have conducted a series of experiments to determine what velocity of air can be passed through flared ports before port noise becomes audible. Fifteen ports in a range of diameters and flare sizes were tested, leading to the following observations:- Maximum usable velocity varies with flare radius

- There is a limiting velocity for any given diameter port, regardless of flare radius

- Larger diameter ports have a higher usable velocity than smaller ports

- Port performance varies with frequency

The following pair of tables show the default recommendations for some common port / flare combinations. Selecting different options, such as allowing some port compression can change these values.

They show the maximum allowable port velocity in metres per second, so that turbulence will not be noticable at the typical Home Theatre seating position. The core limit is where the air in the "core" of the port becomes turbulent, regardless of flare size. Combinations that are core limited are shown in red

The first table is for a sub whose peak velocity occurs at 30z. The second table shows what happens when the velocity peak is at 20hz - note the drop in performance

Useable velocity at 30hz

| Port diameter --> | 50 mm | 86 mm | 100 mm | 150 mm |

| Unflared | 4 | 7 | 8 | 16 |

| 10mm flare | 7 | 10 | 12 | 21 |

| 13mm flare | 9 | 11 | 13 | 22 |

| 25mm flare | 15 | 17 | 19 | 29 |

| 30 mm flare | 15 | 19 | 21 | 31 |

| 35mm flare | 15 | 22 | 24 | 35 |

| 40 mm flare | 15 | 24 | 27 | 38 |

| Core Limit | 15 | 24 | 30 | 38 |

Useable velocity at 20hz

| 20hz Port diameter --> | 50 mm | 86 mm | 100 mm | 150 mm |

| Unflared | 2 | 4 | 5 | 10 |

| 10mm flare | 5 | 6 | 8 | 13 |

| 13mm flare | 5 | 7 | 8 | 14 |

| 25mm flare | 9 | 11 | 12 | 18 |

| 30 mm flare | 10 | 12 | 13 | 20 |

| 35mm flare | 10 | 14 | 15 | 22 |

| 40 mm flare | 10 | 16 | 17 | 24 |

| Core Limit | 10 | 16 | 20 | 25 |

As a general rule, the minimum port diameters should be as shown below.

Always check the velocity in your design. For high excursion drivers you may need more portage.

| Driver size | Minimum Port Diameter |

| 08 inch | - |

| 10 inch | 4 inch |

| 12 inch | 5 inch |

| 15 inch | 6 inch |

| 18 inch | 8 inch |

Clearance around port intake

Where possible there should be no wall closer to the port intake than one port diameter. When using a flared port, the ideal clearance should be the diameter of the flare exit.Where this is not possible, aim for one port diameter clearance from the outside edge of the flare. If your port is a bit closer to the back of the box, maintaining plenty of clearance around the sides of the port exit will minimise possible turbulence and tuning changes.

Good Bend, Bad Bend

Not all bends are created equal. A good bend has a gentle turn, and introduces no sharp edges to the airflow.

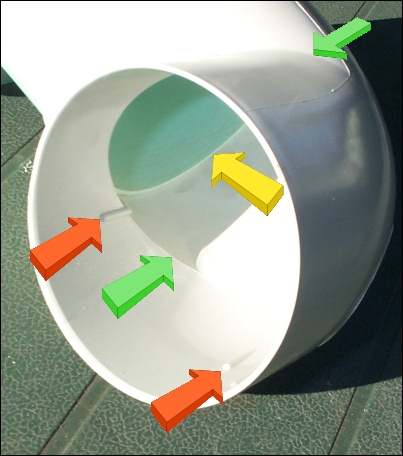

The first picture shows an elbow with a hard 90degree turn on the inside, indicated by the green arrow. This will cause turbulence, even at low speed.

At higher speeds you may even get whistling

This next picture shows another view of the sharp bend (green arrows). You can also see that the joiner doesn't provide a clean transition between the elbow and the pipe. Because there are only some small locating ridges (red arrows) rather than a continuous junction, the hard edge of the pipe (yellow arrow) is presented to the airflow

Much better. The inside bend (green arrow) is nice and gradual. This elbow also provides a full surface (yellow arrow) for the pipe to butt up to, making for a seamless transition. This style of bend is sometimes called a Long Turn Quarter Bend

If you are purchasing PVC elbows, bear in mind that one of the papers on the AES site recommends that the minimum bend radius

should be 20% of the port diameter. If your supplier only sells bends where the inside bend is a sharp 90 degree step,

try and find an alternate source.

If you can't find a nice gradual bend, you can use several less severe bends, as shown in this picture, courtesy of Wolfgang Krieger from Munich

If you are stuck with one of the less than perfect bends, make sure you sand off any sharp edges

Port Compression

As larger port flares allow velocity to be lifted without turbulence, port compression becomes an issue

Port flares allow a controlled change in velocity as air exits a port.

This can prevent turbulence in the boundary layer, close to the port wall, from becoming audible.

As the airspeed is lifted a little further, turbulence within the straight section

of the port becomes an issue.

The reason a ported speaker works is because the air in the port causes a 180 degree phase shift

in the air behind the driver. When the air comes out of the port, at least at the tuning frequency,

it is in-phase with the front of the driver, giving a boost to the output.

As air in the core of the port becomes turbulent, this phase shift decreases,

thus reducing the in-phase contribution made by the port.

The total output of the box no longer rises at the same rate as input power is increased,

and the port is said to be compressing

Eventually the port acts as a mere hole in the box, short circuiting the acoustic output of the driver

and allowing excursion to become uncontrolled.

The compression of an unflared port worsens in a steady curve.

A flared port "hangs on" for longer, and then quickly plummets. Ultimately both ports fail at the same level

which represents completely turbulent flow throughout the port.

Much like a car racer using slick tyres, the trick is to use the extended capability of a flared port

whilst making sure it's not pushed to the point where it "lets go"

Factors which come into play include air velocity, port diameter, port length and port flare radius.